SINOLIGHT Aluminium Profile

As a kind of light metal, the content of aluminum in earth is just next to iron, since the invention of electrolyzation of aluminium in 1886, the application of aluminium has been comprehensive all around world.

From 2005, Chinese government began to abandon low grade aluminium capacity and integrate prime manufacturers to realize the new generation and production of aluminium production in China. Under such background, SINOLIGHT Aluminium mergered Mirach Metallurgy Co., Limited in the end of 2010.

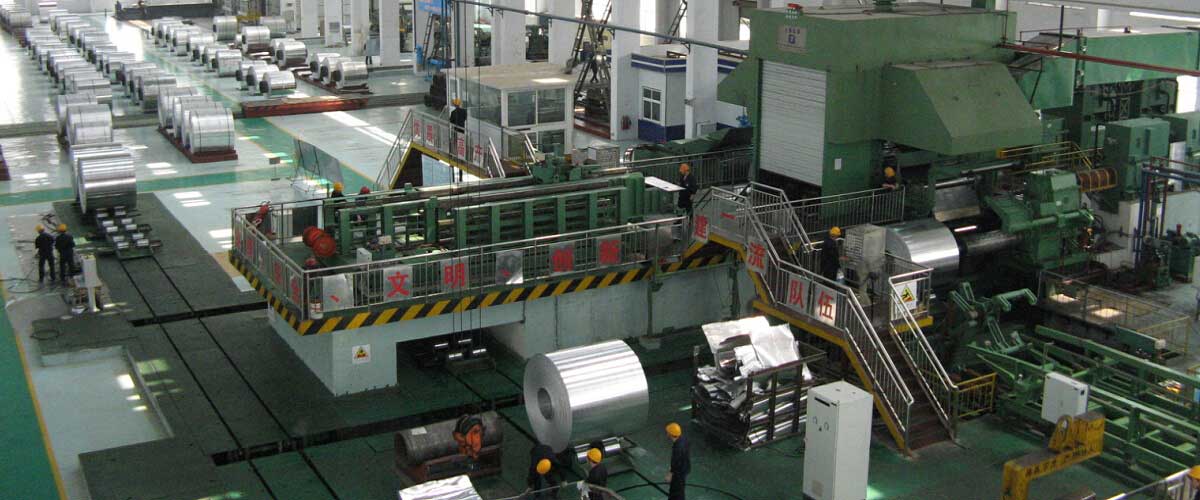

Now, SINOLIGHT Aluminium is recognized as the largest aluminium processing enterprise in China for its leading facilities and equipment with modern technology and specialized in lithographic quality coil for offset printing, aluminium discs/circles for household appliance, and prepainted coil/sheet for construction and decoration.